Laminates

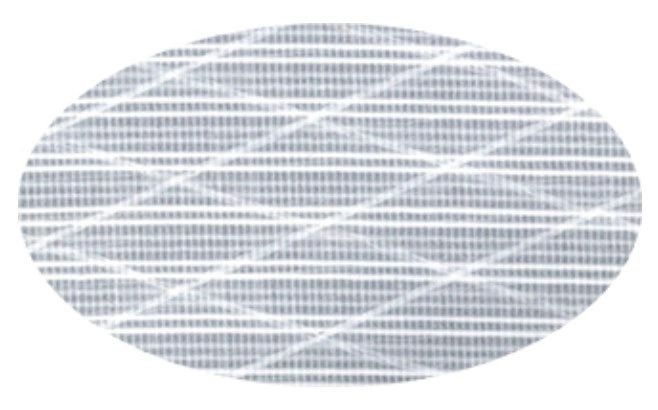

The Laminates came up mostly to avoid the “Crimp” of the weaves so that we have better straight-forward pulling, depending of the direction of the fibers and the panel layout in each sail. The goal is to get the right panel layout with the right fabric so it will respond to the wind force. Laminates that are constructed today aren’t like those ten years ago. Now the yarns are unwoven and laminated mostly with polyester film, heated at 220 degrees with modern High-tech textile machinery.

The scrims of yarns that are laminated are from Carbon, P.B.O., Kevlar, spectra, Vectran, Pentex, and polyester and who knows what synthetic fibers will pop up tomorrow !

These make the difference and the allocation that are formed in each laminated fabric, to resist the main and secondary forces that each sail has to respond to.

Laminates may be constructed in quite a lot of layers. Today you can laminate two or more scrims with layers of Mylar film or Taffeta. Taffeta is a layer of light polyester weave, which strengthens the fabric and helps it when the sail is flattered. It also helps in UV resistance.

It depends in what type of sailing you do to choose the right laminate.

You may have laminates either you cruise or Race or anything in between. If you want to keep the sail shape that your sailmaker gave you, make your sails laminate. If you’re racing the type of laminate to use depends on your class rules and the measuring system that your boat is racing.

The budget is something that counts since some of these laminates are quite expensive but, yes, they make a difference.

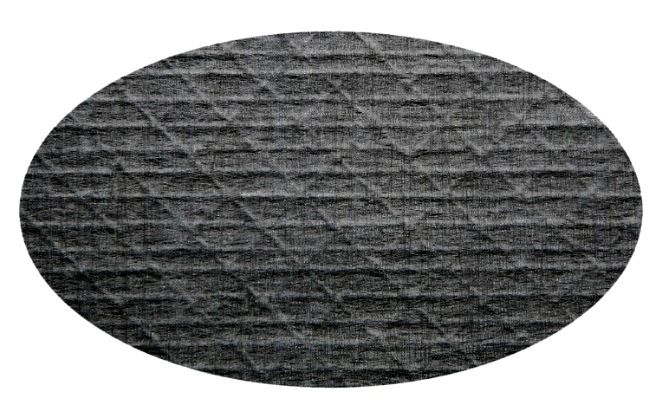

Gallery

Aramid Black

Aramid Sport LS

DYS (Spectra Laminate)

Code Zero PES

CS SPORT LS

DCX Tafetta Mylar

Flex Sport

Flex Ultra

PX Black Line

Copyright © 2020 www.Kakitsisailmaker.com

El.Stromatias